Each production line is different. Universal software does not exist.

So how is it possible to standardize software for production lines?

With PL Framework. It contains multiple apps which can help to design,

simulate or control production lines based on small services.

Standard platform offers more than 10 useful services.

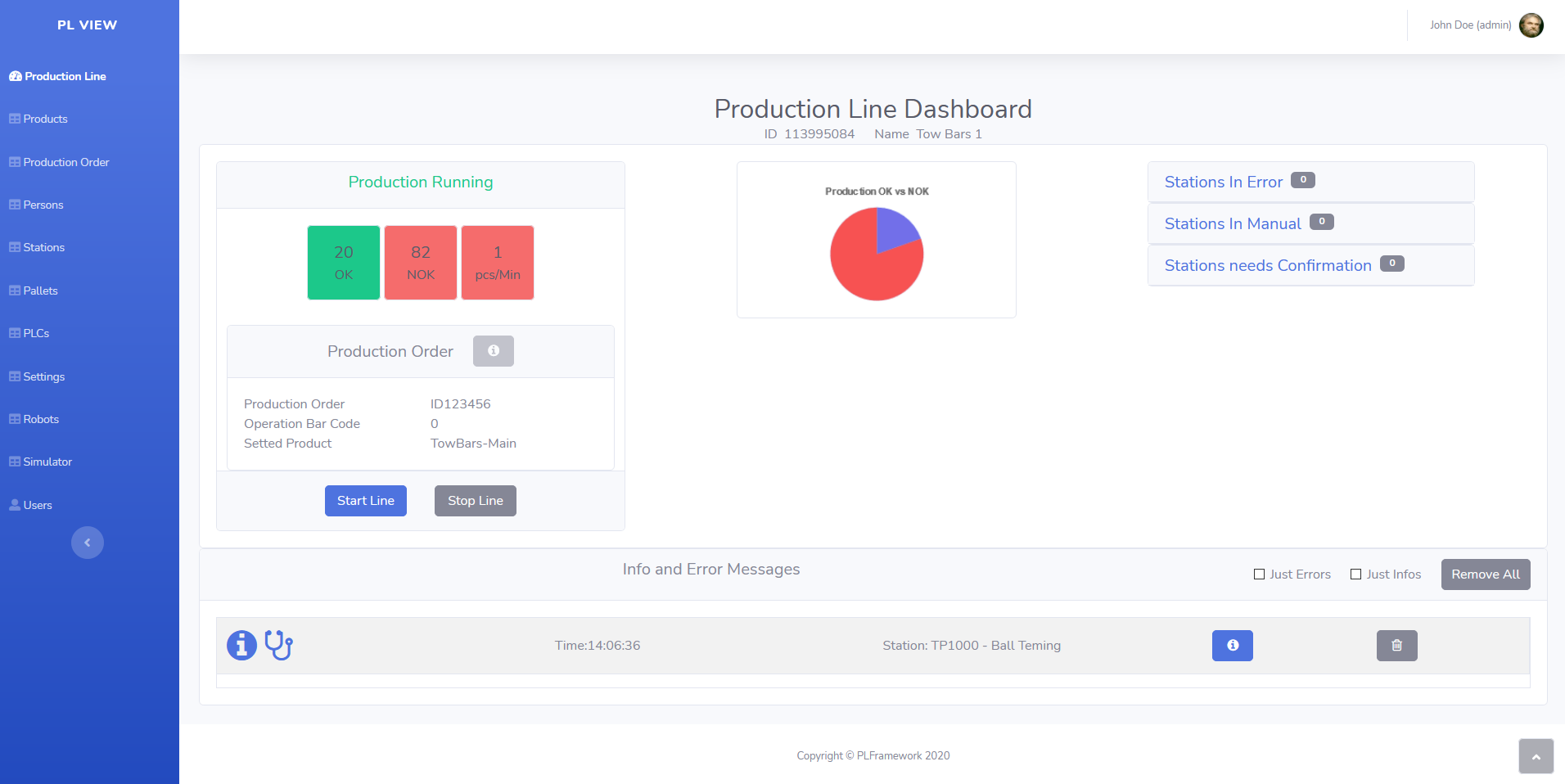

If you want to access to your production line from any device or any place, there is a simple solution:

Web Based UI!

Easiest and cheapest way how to build web based UI for your production line. Most of the features are already included in PL View and PSB View. You can also easily add your customized dashboard.

This century is data driven.

Production lines can offer lots of useful data, which helps to improve

quality and quantity, no matter what you produce.

Lots of energy is required to get datasources after production line is designed.

PLF comes with the solution. PLF already provides useful data sources in according to

Industry 4.0 visions.

Typical Applications

PL Framework is designed for assembly production lines. Usually production lines with tact time over 1s.

- Automotive parts production

- Electronic devices production

- Food Industry

- Testing laboratories

- Data Acquisition

- Simulation of processes on production lines

- Process Time optimisation

- Measuring pallet handle time on old production lines

- Data acquisition from ABB Robots with IRC controllers

- Control of small stations or workplaces

- Control of whole production lines

- Grabbing data about cycles from old production stations

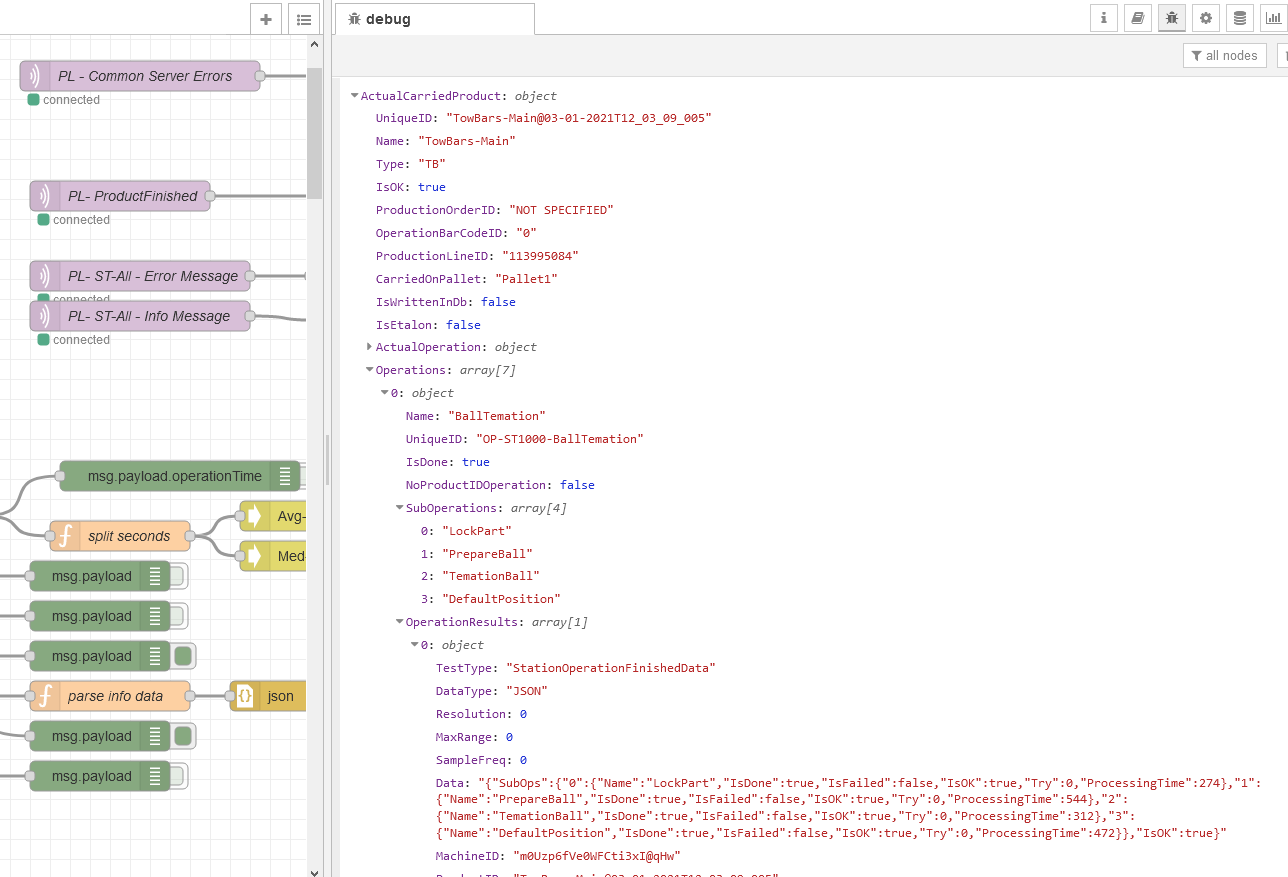

Simulate production lines

With PL Framework you can easily design processes and its parameters in the simulator. It will help you to find bottlenecks and places for improovement. Your settings can be used on real production lines. You can save and analyze all settings and logs later or share with your colleagues on MS Teams and GitLab. Simulator can be also used as a acquisition software for any production line with our HW.

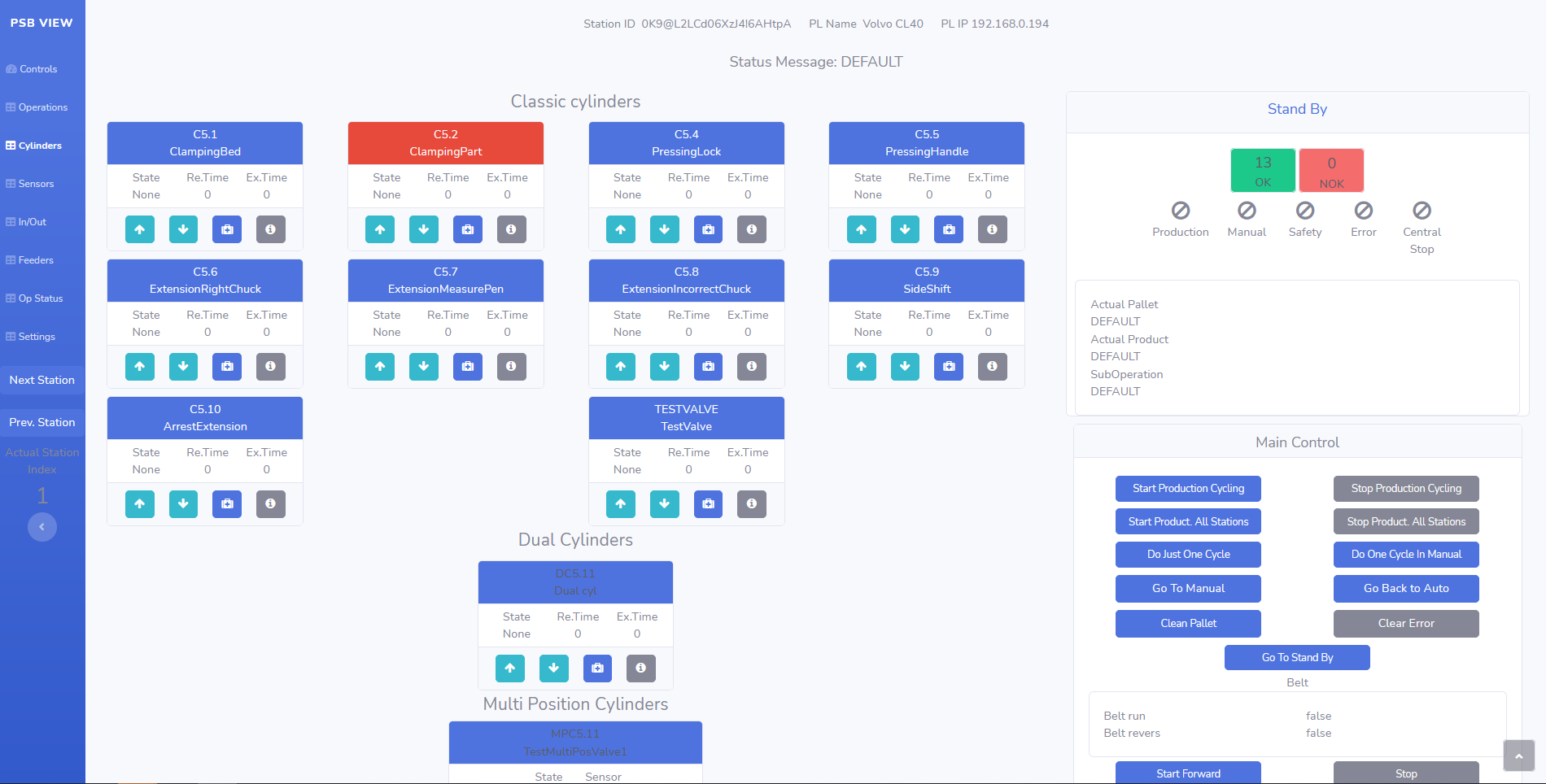

Create production lines

It takes under one hour to prepare new computer with Windows or Linux

to run whole PLF services.

Then you can easily create settings, products and users for stations with web UI.

You can use the same UI to test production lines

or to run in full automatic mode with all data sources.

- Cylinders

- Analog Sensors

- Digital IO

- Vibration Feeders

- Stepper Motors Festo

- Marking Lasers, LINX and Mepac

- QR and Bar Code readers Keyence

- Keyence Cameras and Basler Cameras

- ABB Robots

- B+R Automation PLCs and Servo Axes

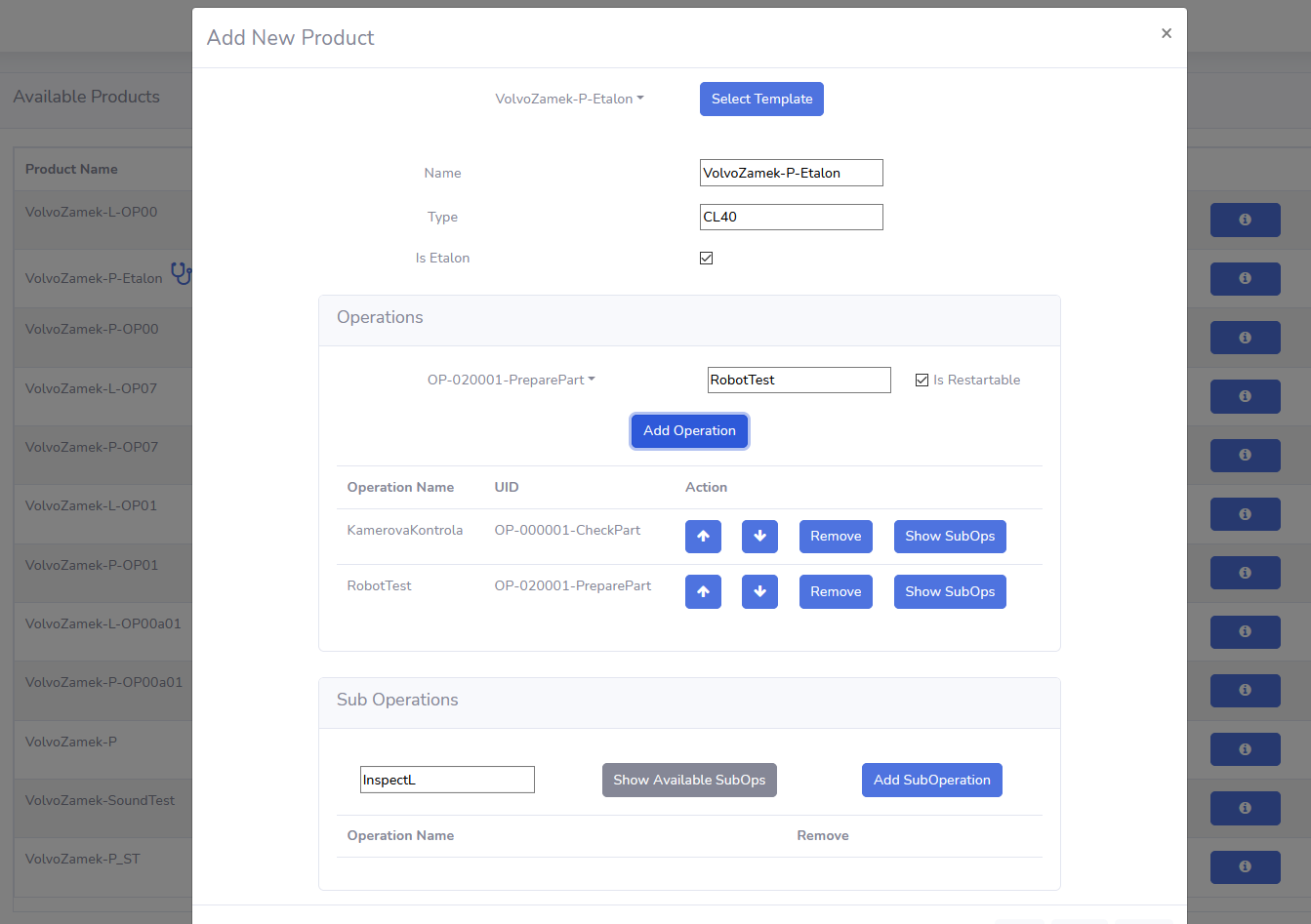

Create Product recipes

In most of cases, multiple versions of the same product have to be produced on the same line. This issue includes also testing of stations with etalons and putting reworked products back to the production.

In PL Framework, you can easily setup all of these cases with PL View. The recipes can be changed during the production and you can use multiple scenarios on the same time. That means you can test etalons during production.

Product recipes are created from operations and its suboperations. Operations and suboperations are provided by stations in the production line. You can then combine and define order as you need.

Dynamic Reconfiguration

One of the vision of Industry 4.0 is dynamic reconfiguration of production.

This reflexion is to increase inqury for customisation of products.

Each product can be little different because its customer wants it.

21st century production line must take this into account.

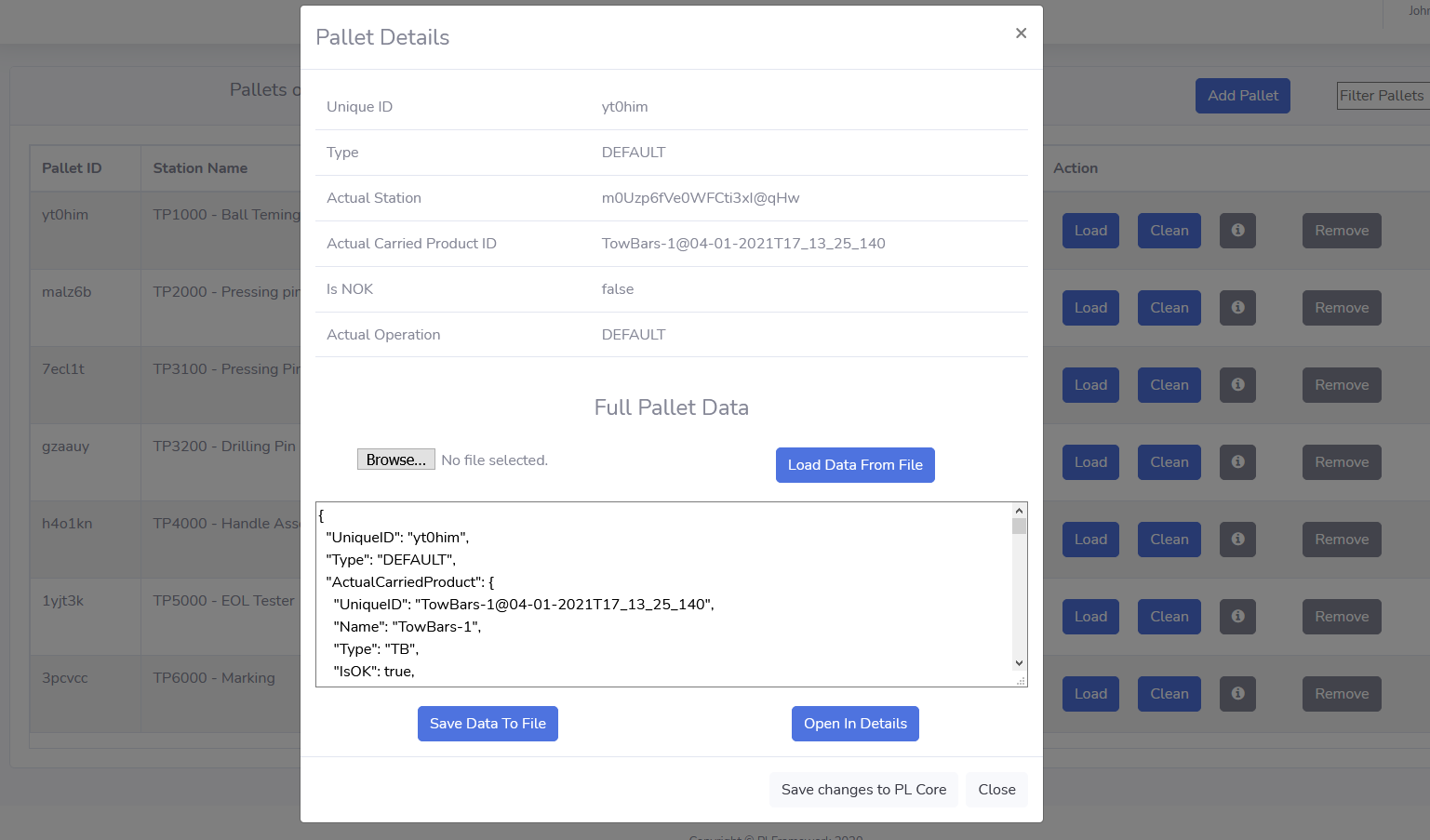

PL Framework is driven by pallets.

Virtual Pallet Object keeps the data and when station receive a pallet

(even some virtual ID) it can request information about the product and what should it do with it.

This offers amazing opportunities to create testing sequences for all the

station and test and upgrade production lines during production.

Or you can just benefit from simple product creation and running multiple

versions on one production line.

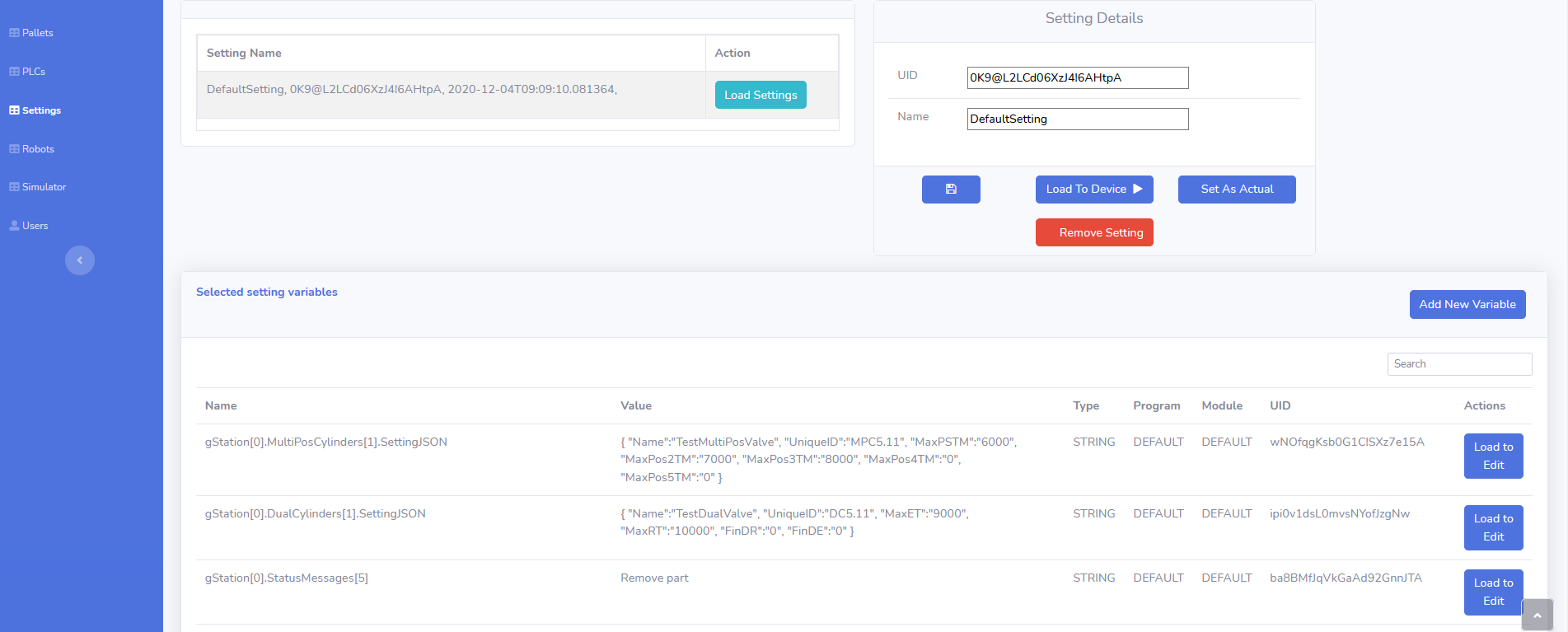

Save & Control Settings

Production lines are made with many technologies with multiple parameters. PL Settings create space to standardize the most of the parameters you need to set and store on production lines. It keeps the data in PostrgeSQL database with timestamps and informations about manipulation. You can track who changed the parameter on the production line and when it was changed. This is standard functionality of PL Framework. No need to program it, just use it.

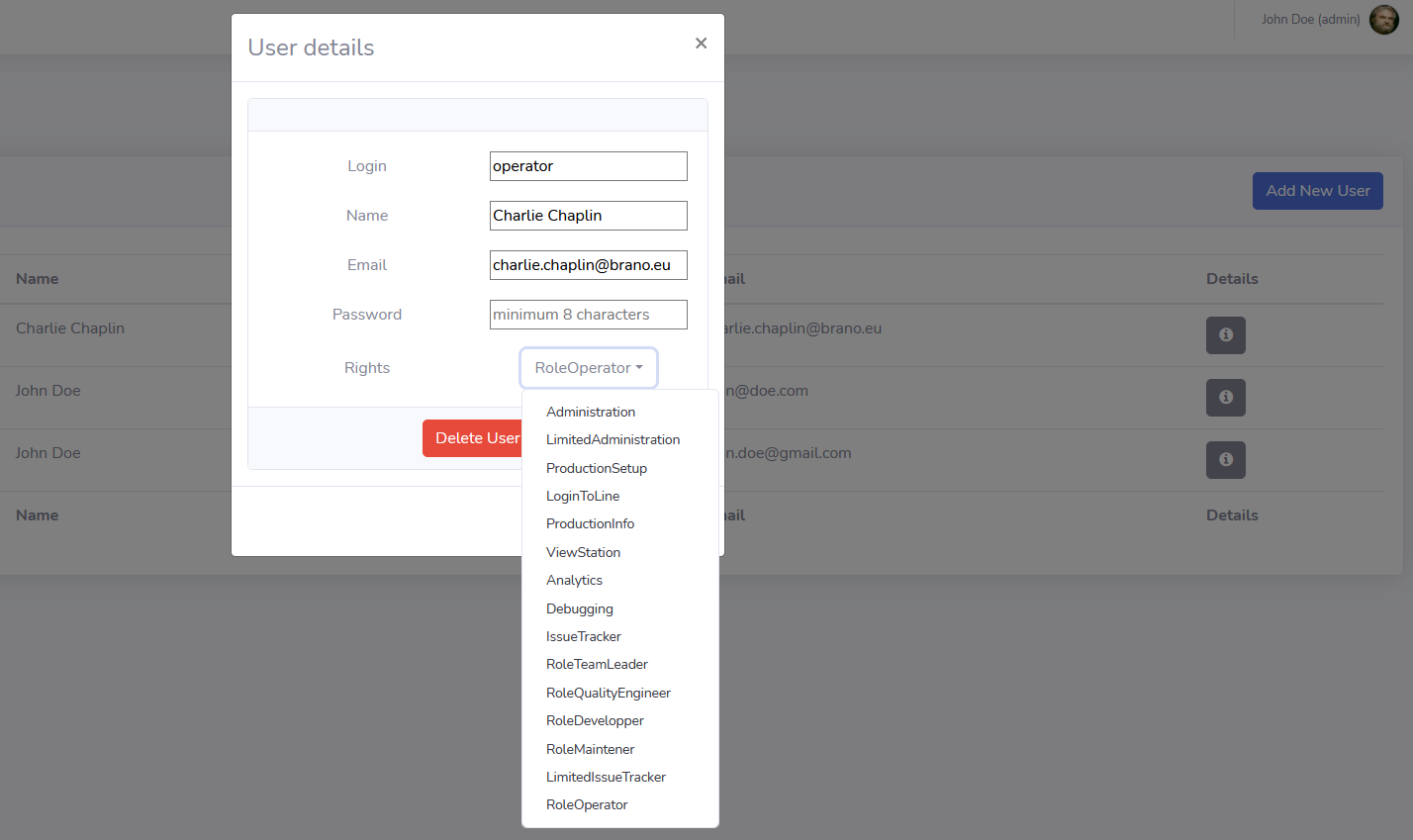

Rights and access control

Production lines are operated by teams. But usually not all team members should have the same rights to control production lines. Handling users rights is not easy on PLCs and there is hard-coded password most of the time. PL Framework contains API for users and rights administration. User table is stored in databaze on local or remote PC. It helps to centralize the users and rights administration.

Easy to Use & Customize

PL Framework offers many ways for customisation. Basic customisation starts with creation of products and stations. Then you can create customized dashboards for any station in HTML/CSS/JavaScript.

Main field of customisation comes in station. Its operations must be defined by the programmer because they are based on exact situation. You can use template with open source for PLC or PC application which can be simply changed for any purpose you need.

Actual Templates are available for: B&R PLC (ST), C#, Python, Arduino, JavaScript

Access data, analyze, feedback

It takes under one hour to prepare new computer with Windows or Linux

to run whole PLF services.

Then you can easily create settings, products and users for stations with web UI.

You can use the same UI to test production lines

or to run in full automatic mode with all data sources.

- Cylinders, Analog Sensors, Digital IO, Vibration Feeders

- Stepper Motors Festo

- Marking Lasers, LINX and Mepac

- QR and Bar Code readers Keyence

- ABB Robots

- B+R Automation PLCs and Servo Axes

Main PL Framework Applications

PL Economy

A digital twin of economy in business. With PL Economy, you can track your business property value in real time, plan dynamically and create your own currencies to control various economical tasks in your company. Connection with blockchain, cryptocurrencies and their exchanges.

PL Core

Main control core. This service handles pallet data and informations about test results, active persons, production orders etc.

PL Stations

Digital twin of stations. Main function is central data republishing from stations but it also works as powerful simulator of actual production lines.

PL View

Main UI for all services. You can control whole production line from one modern web interface on production line panel, your laptop, tablet or mobile.

PL Settings

Service which keeps your stations and technologies parameters updated and saved. One for each production line or one central for each line.

PL Marking

Service with drivers for marking devices. Now contains drivers for industrial laser markers from multiple producers.

PL Robot

Connection between PLC and Robot was never easier. This service offers simple way how to have asynchronous communication with industrial robots. Now it supports ABB. Others coming soon.

PL Pallet ID

This service communicates with QR, Bar or RFID code readers. It is necessary for product tracking during whole production chain

PL Vision

PL Vision communicates with cameras Keyence or Basler. It makes machine vision systems integration easier.

PL Mobile

Receive notifications from production line to your mobile phone or tablet. Read QR codes with Production Orders data, read operators RFID tags and more

Main Technologies

NEBLIO

Neblio is a secure, distributed platform built for enterprise applications and services.

.NET Core

.NET Core offers multiplatform environment to build powerful applications. You can run PLF Services under Windows, Linux, Android,

and MacOS.

Important part of .NET is ML .NET which is great Neural Network SDK

MQTT

Publishing of messages is very important technique in IoT communication. MQTT offers simple but also strong way how to publish data for view or other systems.

PostgreSQL

Powerful open source object-relational database with over 30 years of active development. Multiplatform solution.

HTML / CSS / JavaScript

All user interfaces are created in HTML, CSS and JavaScript. It uses minimum dependencies. Usually just Bootstrap and jQuery. It is very easy to edit and customize any of UIs.

Structured Text

Template of PLC Station code is written in Structured Text based on IEC 61131-3. It is very easy to build it on many industrial platforms.

Swagger

All PL Apps which offers REST API provides specification in format for Swagger. If you need to build your UI or connection from other system, this will save you a lot of time.

Pricing

Online PLF Tools

Online Access offers tools to design whole process, setup simulator, and simulate production line. You can also connect IoT nodes to acquire data from real production lines.

- PL Configuration Tool

- PL Simulator

- PL Data acquisition and analysis

- IoT Connector for data acquisition

SOON

Standalone Light

This is distribution for one production line or Robot workplace. Full package of PL Applications.

- PL Configuration Tool

- PL Simulator

- PL Data acquisition and analysis

- IoT Connector for data acquisition

- License for standalone PC (works also without internet)

- PL Robot, Marking, Vision, and other applictaions

SOON

Standalone Standard

This is distribution for one production line or Robot workplace. Full package of PL Applications.

- PL Configuration Tool

- PL Simulator

- PL Data acquisition and analysis

- IoT Connector for data acquisition

- License for standalone PC (works also without internet)

- PL Robot, Marking, Vision, and other applications

- PL Core services

SOON

OEM

If you need PLF for multiple production lines, please contact us to get OEM price offer